DRAWING and STAMPING FLUIDS & LUBRICANTS

Contact Us Today

ETNA Products, Inc. has over 70 years of experience developing, formulating, and manufacturing neat oil and water soluble oils for deep drawing and stamping operations. When ETNA started operations in 1943, we began providing our drawing and stamping fluids and lubricants to produce shell cases for ammunition. Our drawing and stamping fluids and lubricants were also used to produce primer cups, full metal jackets for bullets, blasting caps for munitions and more. Now, our MASTERDRAW® and DAPHNE®* drawing and stamping fluids and lubricants are used in a variety of applications, ranging from stamping high volume automotive parts to producing miniature parts used in medical devices.

We offer a wide range of drawing and stamping fluids and lubricants, including water soluble oils, neat oils, and solution synthetics. Additionally, ETNA Products, Inc. provides custom formulations to meet specific customer requirements. All of our metalworking fluids and lubricants have been formulated to help our customers extend tool life while maintaining tight tolerances and improved surface finish on the final parts.

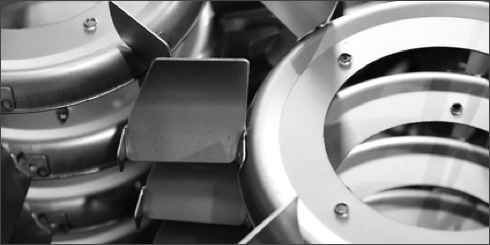

Metal Stamping & Drawing

Our extensive line of MASTERDRAW® and DAPHNE®* drawing and stamping fluids and lubricants will suit any sheet-metal forming process, whether it be blanking, coining, embossing, flanging, or punching. Our water soluble oils are environmentally friendly and go far beyond the lubricity provided by standard drawing fluids.

ETNA Products Inc. offers drawing and stamping fluids and lubricants for both ferrous and nonferrous metals at any thickness. No matter if you are stamping copper for full metal jackets, stamping brass for primer cups, or drawing brass to produce shell cases, ETNA offers custom product formulations and ideas to improve the tool life of your stamping or deep drawing machine.

Our product line of MASTERDRAW® and DAPHNE®* drawing and stamping fluids and lubricants are formulated with a wide variety of lubricity additives designed to reduce die marks and to prevent galling during stamping and drawing operations. Our water soluble oils are specially crafted to resist bacterial contamination and they exhibit excellent anti-weld properties to hold up against the toughest stamping operations, such as stamping carbon alloy or nickel based alloy metals.

We offer deep drawing fluids and lubricants for both ferrous and nonferrous metals, and our products are designed for use on both single and multiple drawing processes to withstand high pressure and prevent scoring at the workpiece to die surface. Do not risk the life of your stamping or drawing dies by using sub-standard lubricants. We offer drawing oils for highly complex deep drawing processes, such as deep drawing eyelets. Harder metals require greater lubricity, so it’s critical that you provide the best metal forming lubricant to preserve the surface finish of your products, as well as your tool life.

Our metal forming lubricants can withstand the high temperature and highly complex operations of metal stamping:

- Brass

- Stainless steel and nickel based alloys

- Aluminum

- Graphite

- Carbon alloys

- Bronze

- Copper

Cleaners and Rust Preventatives

In addition to manufacturing drawing and stamping fluids and lubricants, ETNA Products, Inc. offers aqueous cleaners and solvent based cleaners sold under the MASTERALL® and DAPHNE®* brand names. These cleaners are used to remove excess residue from the metal piece that has been stamped or drawn. Our specially designed aqueous cleaners can be used at ambient temperature to help our customers save energy. In addition, several of our synthetic based aqueous cleaners can be used to clean ferrous metals, and the residues may provide temporary corrosion protection on the parts.

We also offer a complete line of STEELHIDE® corrosion inhibitors and industrial rust preventatives to protect the appearance of your finished parts. Choose from water miscible or neat oil products that provide corrosion protection on the parts. We offer products that form a dry or waxy film. Our rust preventatives may also be used to protect your die sets during storage.

We will work with any customer request to help you preserve the performance of your tooling while allowing the production of top quality finished parts.

- MASTERDRAW® SOL G with EELT™

An amber emulsifiable non-chlorinated oil used for drawing and stamping ferrous and non-ferrous metals with thicknesses up to .040”.

- MASTERDRAW® SOL 3950

A water miscible oil used for drawing and stamping operations of ferrous metals with thicknesses up to .250”.

- MASTERDRAW® SOL S with EELT™

A versatile, heavy duty non-chlorinated soluble oil that may be used for drawing and stamping ferrous and non-ferrous metals.

- MASTERDRAW® G with EELT™

An amber emulsifiable non-chlorinated oil containing a unique blend of extreme pressure and lubricity additives developed for light to medium duty stamping operations.

- MASTERDRAW® SYN H

A heavy duty water miscible synthetic fluid used for drawing and stamping ferrous metals with thicknesses up to .090”.

- MASTERDRAW® SSY-G-4200

A water miscible semi-synthetic drawing fluid designed to highly effective, and fortified with sulfurized E.P. additives designed for drawing and stamping ferrous metals.

- DAPHNE® OIL COAT RL55NB U

A transparent, dark amber solvent based fluid used for stamping. Formulated with an excellent rust and corrosion inhibitor package for ferrous metals.

- DAPHNE® OIL COAT RL55 F-U

A transparent, dark amber solvent based stamping with an excellent rust and corrosion inhibitor package for ferrous metals. No added barium.

- MASTERALL® 6050B

A dark, brown colored non-chlorinated neat oil used for deep drawing non-ferrous and ferrous metals.

- MASTERDRAW® 6054AC

A light amber colored non-chlorinated neat oil used for deep drawing carbon and stainless steel.

- MASTERDRAW® 727

A heavy duty neat oil used for deep drawing ferrous and non-ferrous metals.